|

Electrics

Wiring

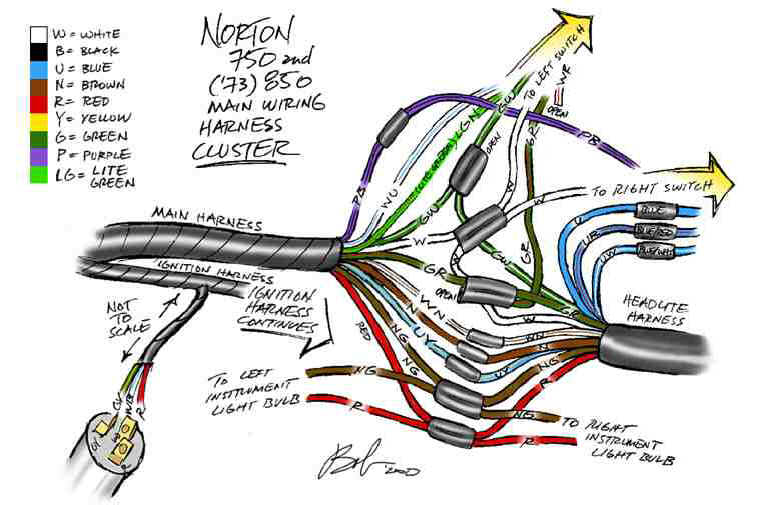

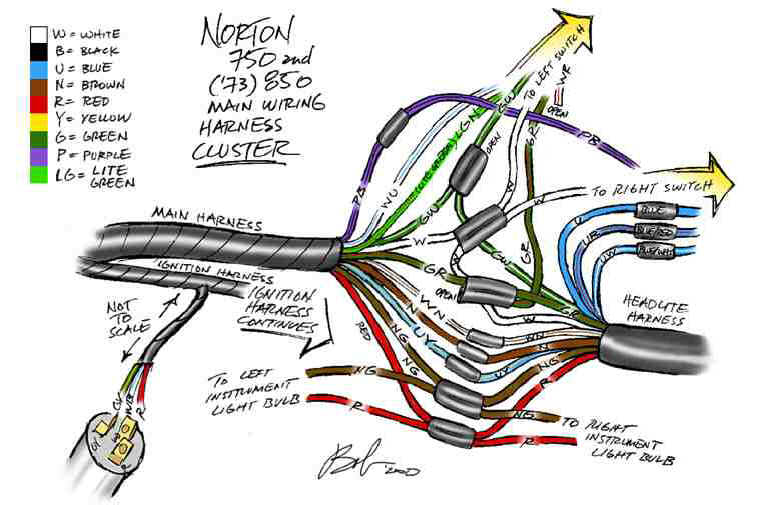

Harness Diagram - / - Wiring

Wizardry - / - Has Anyone Zener? - / -

Lucas

Service Information

[Joe

Lucas' Treatise on the Importance of

'Smoke'] [Lucas - Prince of

Darkness]

[Click here for a complete guide to Lucas Electronics.]

Return to Library Contents

by Bob Cox

Wiring

Wizardry

Some tips for wiring vintage bikes.

1) Use 16 awg, stranded copper wire. Make sure that the insulation is

thick, to protect from abrasion.

2) Avoid the cheapie connectors marketed at after market auto shops. The

AMP company makes 1/4" Faston spade connectors. Theses are used in many automotive,

electrical / electronic & industrial applications, and they can be purchased from

various suppliers to those industries. An especially nice style is the one that has the

connector totally enclosed in plastic, so when the connector is mated, the male and female

ends interlock to keep out dirt.

3) The plastic harness wiring covers are good to keep the wires together

in a bundle and out of harms way. They also add an extra layer of abrasion protection.

Tape the cover at regular intervals to keep the wires inside & from bulging open

around bends.

4) To ensure having the electric’s working all the time, use an

independent ground wire to connect your headlight, instruments, taillight, and other bits

directly to the battery ground.

5) To add extra protection,

(a) slather them with dielectric grease to protect from corrosion

Edited from the Internet

Return to Top of Page

Has Anyone Zener?

Hello ?! "Has anyone seen my zener." Or in the German,

"Has anyone seen mine zener?"

What the hell is this thing with a name that beings with the last letter

of the alphabet and why should we care?

The Zener diode's job is really to act as an automatic valve that dumps

excess electricity as required. To be technically correct, it is a voltage-sensitive

semiconductor that only begins to conduct once the applied voltage reaches a certain

"zener" threshold. At that point, the Zener begins to conduct more and more

current, with very small incremental increases in its applied voltage. Since the Zener is

effectively in parallel with the alternator via the rectifier, the applied voltage is the

alternator's rectifed output: the Zener senses and dumps any excess electricity from the

alternator by converting it to heat.

So, if your alternator is low on output, or other things use up the

available power (like headlamps being on all the time in Norway), it's pretty clear that

the Zener won't have much work to do: there isn't any excess electricity to deal with, because it: 1) isn't being generated in

the first place, or 2) something like a high power headlamp is using it instead.

A higher voltage Zener can only help by letting the system output rise

further before the Zener starts dumping electricity. A Zener can't compensate for a weak

alternator, or excessive loading on the system. So on the flipside, in a properly

operating system, removal of the Zener, and running with lights off can be disasterous

because there's nothing there to shed the excess generated power.

Lucas's use of a Zener is pretty unsophisticated, since Zeners require a

series resistance in the system to protect them from self destructing as the input voltage

increases. (It's output voltage is not temperature

compensated either, the way lead-acid batteries like it to be). Lucas

simply relies on the internal impedance of their alternator to rapidly choke down the

available output voltage as the Zener comes on.

Reprinted from the Internet

Zenor Diode Comments

By Robert Baucom

Concerning Lucas electrics and Zenor Diodes ALWAYS make sure the Battery has a GOOD GROUND

connection. At both the battery post and the frame connection. No

corrosion allowed. (first wash with solvent, then Bicarb of soda), scrape,

sand, bolt up and cover with grease (Silicon grease if you have it). There

are now available, some neat, Hi-Temp greases associated with auto disk brakes.

The reason this is so important: When there is a bad ground, you have

resistance. When you have resistance, to obtain proper amperage (current

flow), there is an increase in voltage (pressure). With this excessive

increase in voltage ( the zenor opens at 13.5 volts if I recall) the zenor

is dumping to ground constantly, creating a lot of heat. This destructive

temperature causes that expensive little goodie to fail.

When working for Triumph, in 1970, we held a Dealers Mechanics school in

Okl. City. Dennis Manning (BUB Pipes) of Bonneville Streamliner fame, was

the instructor. Okl. City was on interstate 40 and was the the main,

summer time, conduit from West coast to East coast (or the marijuana

filled creek beds of Kansas). All the Hippy Dippies and other pond scum,

came rattling down the pike on their jury rigged, death trap, Choppers

with their dirty leg gals on the back. Being cool, they were cruising back

& forth from coast to coast, getting sunburned, playing "Easy

Rider" and avoiding their creditors.

One of my OKC dealers was close to said interstate. They got a lot of

chopper trash, traffic with guys wanting to trade "The services of

their scaggy passenger, aka. Giving everyone in the service dept a

"Hot Water Skull Job", in exchange for a new rear tire or chain.

His main mechanic, "Leeroy", was a slightly tattooed, down home,

nose picking, crotch scratching, Harley rider with a slight speech and

pronunciation defect ... He spoke out, "Why do these here Zen-E-R

Die-odes cost so much money ($23 at that time)? The customers think I'm uh

try'n to rob'um when I tell 'um they needs uh new Zen-are!" There was

a group murmur, validating his query.

Dennis went into a technical dissertation, explaining the Zenor was

really an electrical valve: manufactured to complete a circuit at a

predetermined value of EMF. When the EMF exceeded this predetermined

voltage, the molecular construction of it's internal components changed:

thereby causing the "valve" to establish continuity to the outer

body and/or ground.

Leeroy's (that really was his name) eyes glazed over for a moment. His

eyebrows worked up and down a few times, as he mentally tried to digest

all these "Physics Class", unfamiliar, technical terms. He

closed his slackened jaw, stood up and asked, "Have yew ever tried to

Ex-plain, Mo -lek-uh-lar Con-stuck-shun to a 'Hells Angel'? ... Everyone

in the room, including Dennis, exploded with laughter. Leeroy stood there,

beaming proudly, over having made a "Funny".

Dennis would start to simplify his explanation and then self distruct with

laughter. After three of four tries, he wiped his eyes and said,

"Tell the dumb son of a bitch, It's a top secret. If you told him,

then you would have to kill him!" A still grinning Leeroy,

sarcastically said, "Even kidding around, I'll be damned if I'm goin''

to tell a Hells Angel that, I was a-gonna kill 'em. 'Spes-lee with three

or four of his buddies standing around."

Robert Baucom

Return to Top of Page

Lucas Service Information

Location and Remedy of Faults

Although every precaution is taken to ensure trouble-free

running, electrical faults may sometimes arise and the following test procedure is

recommended.

When checking the continuity of circuits, a flashlamp

battery and bulb should be used. Do not "flash" the end of a live cable to

earth, as this may cause heavy currents which damage the equipment. If a vehicle battery

is to be used, a low wattage bulb of similar voltage must be connected in series with the

circuit to be checked. Never check the continuity of alternator stator windings when the

rotor is in position. The rotor should be removed to avoid demagnetisation and reduced

output.

Battery Charging

Systems

Engine will not start on IGN position:

- Turn the switch to EMG position if

provided. If the engine now starts, the battery is probably discharged. If there is no EMG

position, check the condition of the battery and recharge, if necessary.

- Remove the H.T. cable from the sparking

plug and hold the cable end about 1/8" from a metal part of the engine while the

fatter is turned over. If sparks occur regularly, the ignition system is functioning

correctly. Check for engine defects after examining the sparking plug.

- If sparks do not occur in test (2), check

for a fault in the low tension circuit. Check the wiring from battery to fuse, switch,

coil and contact breaker. If the circuit is continuous, examine the contact breaker and if

necessary clean and adjust the contacts. Also, check the engine timing.

Engine will not start on EMG position:

Carry out previous tests (2) and (3),

check that the alternator rotor is the correct way round on the engine shaft (the name

"Lucas" should face away from the engine).

Engine misfires:

- Examine the contact breaker. If necessary,

clean the contacts and adjust the gap.

- Remove the sparking plug (or each plug in

turn), rest it on the cylinder head and observe if a spark occurs at the plug points when

the engine is turned. Irregular sparking may be due to dirty plugs (which may be cleaned

and adjusted) or to defective high tension cables. If the insulation of any cable shows

signs of deterioration or cracking it should be renewed.

- If sparking is regular at each plug when

tested as described in (2), the trouble is probably due to engine defects, and the

carburetter, petrol supply, etc., must be examined.

- If misfiring occurs after the engine has

been running for some time, check that the ignition switch is in the normal IGN position.

If run continuously in the EMG position, the rising voltage of the battery may eventually

cause misfiring to occur.

A.C. Ignition

Important:

- Keep the contact breaker clean and ensure

the maximum opening is set at 0.014'- 00l6'.

- Keep the sparking plug electrodes clean

and correctly set.

- Keep to the manufacturer's timing

instructions.

Engine will not start or misfires:

- Remove the H.T. cable from the sparking

plug and hold the cable end about 18' (3 mm) from the cylinder block. Sparks should jump

this gap regularly when the engine is turned at kick-start speed.

- If sparks are obtained, check the sparking

plug, reset and clean, or renew as necessary.

- If no sparks are obtained, inspect the

H.T. cable and renew, as necessary. Check contact breaker gap setting.

- If the sparking plug, H.T. cable and

contact breaker gap setting are satisfactory, check for engine defects, faulty fuel

supply, etc.

Charging Equipment Battery in low

state of charge:

- This will be indicated by poor or no

lights when the engine is stationary, and varying light intensity when the engine is

running.

- Check the condition of the battery, and

recharge if necessary.

- Check the wiring from the battery to

switch, rectifier, and alternator. Ensure all connections are clean and tight.

Excessive circuit voltage:

- This will be indicated by burnt out or

blackened bulbs and possibly burned ignition contacts.

- Examine the wiring for loose or broken

connections.

- Check the earth connections to the

battery, rectifier and Zener diode.

- Examine the battery, checking the

electrolyte level and removing any corrosion.

Lighting Equipment Failure of lights:

- If one bulb fails to light, replace with a

new bulb.

- If all lamps fail to light, check the fuse

(if fitted) and check the battery condition, recharging if necessary.

- Examine the circuitry and replace broken

or loose connections.

Lights fade when switched on:

- Check the battery condition, and recharge

if necessary.

Brilliance varies with engine speed:

- Check the battery condition, and recharge

if necessary.

Lights flicker:

- Examine the wiring for loose connections

or damaged cable insulation. Check the battery condition.

Headlamp illumination insufficient:

- If the bulb is discoloured or filaments

have sagged as a result of long service, replace with a new bulb of the same type.

- Check the setting of the lamp and the

condition of the reflector.

Lucas Service Information

Joseph Lucas (Sales & Service) LTD.

Return to Top of Page

Disclaimer: The following information has been collected from various

sources on the Internet and publications for the expressed purpose of providing NTNOA

members with useful information for the enjoyment, maintenance & preservation of old

British & European motorcycles. While the information is intended to be as accurate as

possible it can not be guaranteed to be 100% correct, therefore the reader should use good

common sense and safety before implementing any of the suggestions and ask questions if in

doubt.

Copyright © 2000 NTNOA All rights reserved.

Revised: January 05, 2018

.

|